Manufacturing

Prototyping

An effective proof of concept prototype is invaluable. Prove out models bring the engineering and CAD concepts to life…

Forging

We use the highest-quality tool steels to help assure longevity and part quality..

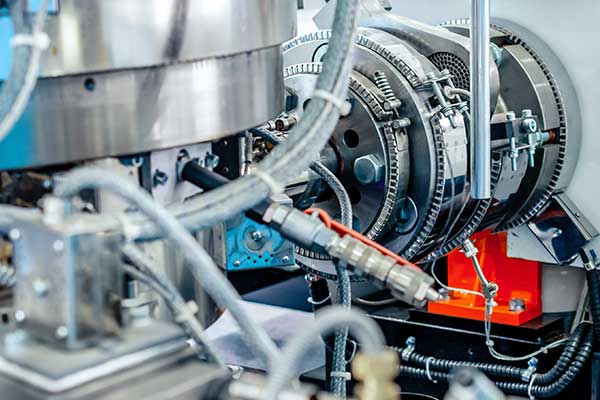

Stamping and Fabrication

At Adapt Technologies, we stamp multiple materials using state-of-the-art processes that will bring…

Plastic Injection

we manufacture a wide range of thermoplastic and thermoset materials with local plastic manufacturers across the…

Machining

We offer precision CNC machining services locally and overseas for companies in every industry…

Packaged Retail Products

We have the ability to produce a wide variety of products complete with packaging…

Electrical

Castings Your Way

We produce high-quality castings to your specifications utilizing various methods.. Our global supply base includes located all over the world including the NA, EU, SA and Asia

Casting Capabilities

• Sand Casting

• Investment Casting

• Permanent Mold

• Die-Casting

Our supply base uses advanced methods to improve overall quality. Our goal is providing high quality castings at a low cost.

Materials

- Aluminum

- Brass, Bronze

- Ductile & Gray Iron

- Stainless Steel

- Zinc

We have experience heat treating aluminum castings. We provide testing for chemical and mechanical properties and thermal stress and distortion on every shipment. We also offer a variety of testing and finishes.

Testing

- Chemical

- Mechanical

- CMM

- Salt Spray

Finishes

- E-Coat, Paint, Powder Coat

- Galvanizing

- Electroplating (Zinc, Nickel, Brass, Etc.)

- Chrome Plating

- Vacuum Plating

We manufacture everything from single low complexity to highly complex parts with low, medium, or high production volume.

We pride ourselves on quality to help your company succeed. We can help you.

Forging

Forgings

We produce high-quality forgings to your specifications utilizing various methods with a supply base is located in the US all other global regions

Forging Capabilities

- Open and Closed Die Forging

- Roll / Upset / Press Forging

- Precision Forging

- Hot and Cold Forging

We use high-quality tool steels to assure longevity and a quality part every time and offer you the best solution for your manufacturing needs.

Materials

- Ductile & Gray Iron

- Steel

- Stainless Steel

- Aluminum

- Zinc

- Brass, Bronze

We have experience heat treating aluminum castings to a proper T4-T7 ASTM standard. We provide testing for chemical and mechanical properties and thermal stress and distortion on every shipment. We also offer a variety of testing and finishes.

Testing

- Chemical

- Mechanical

- CMM

- Salt Spray

Finishes

- E-Coat, Paint, Powder Coat

- Electroplating (Zinc, Nickel, Brass, Etc.)

- Chrome Plating

- Galvanizing

- Vacuum Plating

- Lithographic Transfer

We manufacture everything from simple to complex parts with low or high production volume. Utilizing the latest technologies, we make most any part for our customers. We have implemented in-line processing at these facilities to ensure every shipment follows quality control measures.

At Adapt Technologies, we pride ourselves on quality and innovation to help your company succeed. We can help you.

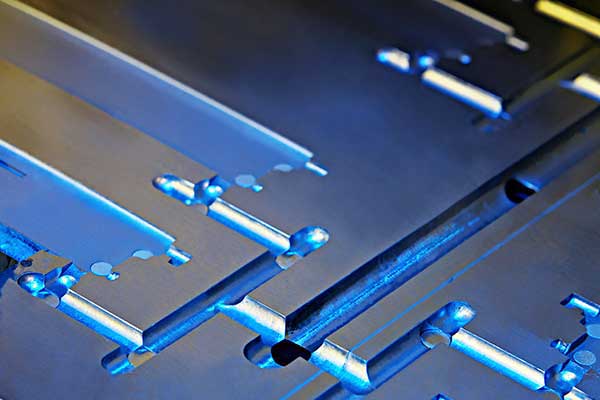

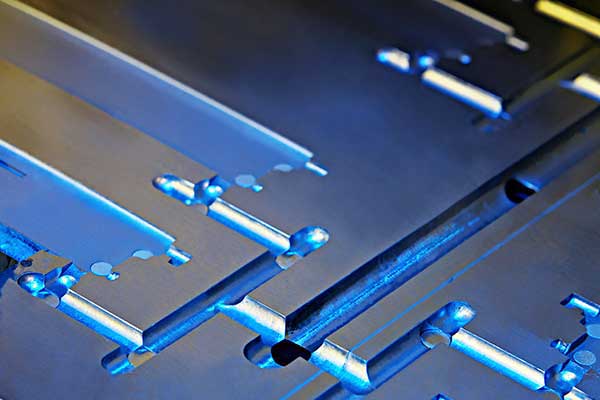

Stamping and Fabrication

Stampings

Adapt Technologies can handle a variety of stamped and fabricated parts of multiple materials by using state-of-the-art processes that will bring high-quality products to industry.

Let Adapt be your one-stop manufacturer for all your stamping and fabricating needs.

Stamping Capabilities

- Press Stamping

- Deep Draw Stamping

- Precision Stamping

- Progressive Stamping

- Coining, Bending, Curling, Flanging, Embossing

Additional Fabrication Capabilities

- Welding (Resistance, MIG, TIG, Friction, Etc)

- Metal Spinning

- Laser / Plasma / Waterjet Cutting

- Roll Forming

- Assembly

In addition to date coding and tracing capabilities to help manage inventory, we offer various testing methods and a variety of finishes.

Testing

- Chemical

- Mechanical

- CMM

- Salt Spray

Finishes

- E-Coat, Paint, Powder Coat

- Electroplating (Zinc, Nickel, Brass, Etc.)

- Chrome Plating

- Galvanizing

- Vacuum Plating

We manufacture everything from simple to complex parts with low or high production..

Plastic Injection

Plastic Products

We manufacture a wide range of thermoplastic and thermoset materials.

Our global supply base is located in the US and in global regions.

Plastics Capabilities

- Injection Molding

- Over mold

- Plastic Extrusion

- Compression Molding

- Roto Molding

- Thermoform

- Vacuum Forming

In addition to date coding and tracing capabilities to help manage inventory, we offer various testing methods and a variety of finishes.

Testing

- Chemical

- Mechanical

- Lead & Phthalate

- FDA

Additional Finishes

- Plating (Chrome, Zinc, Nickel)

- Vacuum Plating

- Chemical Etching

- Painting

- Lithographic Transfer

- Pad, Screen, and Laser Print

We manufacture everything from simple to complex parts with low or high production.. Utilizing the latest technologies, we are equipped to make any part for our customers. We have implemented in-line processing at these facilities to ensure every shipment is inspected to the most rigorous quality control measures.

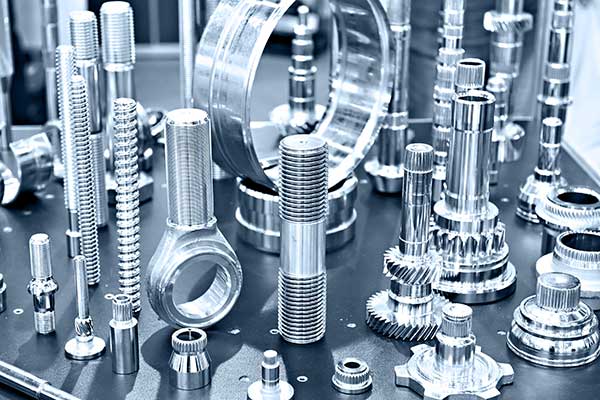

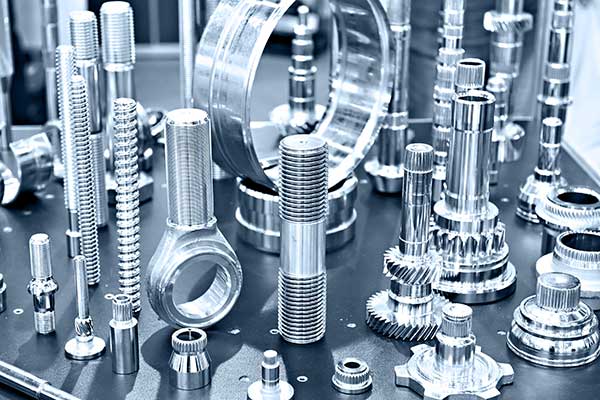

Machining

Machining to Print

At Adapt Technologies, we offer precision CNC machining services for companies in every industry (automotive, consumer goods, off-road, agriculture, etc.) We manufacture everything from simple to complex parts with low or high production volume.

Machining Capabilities

- 2 Axis Turning

- Metal Spinning

- 3-5 Axis Machining

- Screw Machines

- Swiss Turning

- Precision Grinding

- Large Floor Mills and Boring Mills

- EDM

- Molds / Tooling

The Molds we produce quality and performance every time. We believe that good tooling equates to good products. We are the perfect partner to help a company manufacturer their production tools.

We offer a variety of testing and finishes for all our products.

Testing

- Chemical

- Mechanical

- CMM

- Salt Spray

Finishes

- E-Coat, Paint, Powder Coat

- Electroplating (Zinc, Nickel, Brass, Etc.)

- Chrome Plating

- Galvanizing

- Vacuum Plating

- Lithographic Transfer

We manufacture everything from simple to complex parts with low or high production volume. Utilizing the latest technologies, we are equipped to make any part for our customers. We have implemented in-line processing at these facilities to ensure every shipment is inspected to the most vigorous quality control measures.

At Adapt Technologies, we pride ourselves on quality and innovation to help your company succeed. Ask us how we can help you.

Packaged Retail Products

Medical parts to Market

Adapt manufactures fully tested and packaged medical parts and sub assemblies goods. Our vast knowledge of multiple manufacturing methods helps to analyze and finalize the most economical way to produce items for our customers. This, coupled with our ability to streamline processes and improve quality, makes Adapt a leader in this industry.

As your global partner, you gain access to experienced management and global production teams that offer in-depth skills. This includes auditing the facility and making sure they can handle your volume and quality expectations.

Manufacturing Capabilities

- Injected Molding

- Casting

- Forging

- Stamping

- Cut & Sew

- Machining

We offer state-of-the-art printing capabilities that can match your required packaging color, layout, and design. We have the knowledge to offer a complete packaging solution.

Packaging

- Full-Color Display Box

- Heat Seal Blister

- Clamshell

- Hang Tag

- Shrink Wrap

Our goal is to provide the highest quality product to our customers. We utilize several quality procedures to ensure that your product is made to your specifications and to all applicable laws. This includes specific retail audits or compliance requirements.

Testing

- CPSIA

- CARB

- Flame Retardant

- UL

- CSA

- Social Compliance

We manufacture everything from simple to complex parts. Utilizing the latest technologies, we are equipped to make any part for our customers. We have implemented in-line processing at these facilities to ensure every shipment is inspected to the most rigorous quality control measures to ensure quality every time.

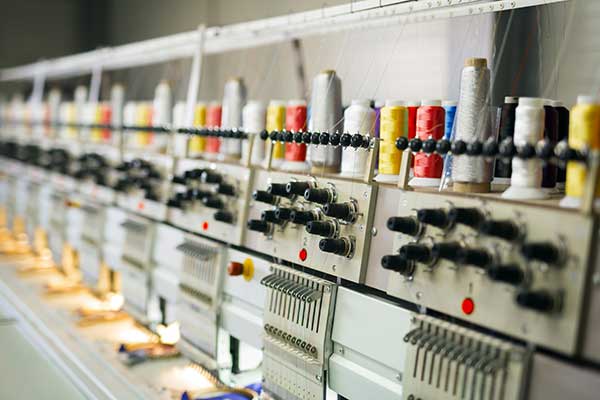

Cut and Sew

Cut and Sew Product

At Adapt Technologies, we produce a variety of cut and sew items from at home physical aid products in hospital products used in a a variety of care units. Our extensive knowledge of multiple methods helps us review items to determine the most economical way to manufacture the product. This, combined with our ability to streamline processes and improve quality, makes us a leader in this industry.

Cut & Sew Capabilities

- High to Low End

- Compression Cases

- Heavy Duty Sewing

- High End Zippers and Clips

- High Thread Pull Capabilities

Our goal is to provide the highest quality for our customers utilizing a multitude of different materials.

Materials

- Nylon

- Lycra

- Cotton

- Vinyl

- Kevlar / Dyneema

Sample Products:

- Bags

- Cases

- Gloves / Clothing

- Outdoor and Indoor Items

- Etc

We manufacture simple to complex products with low, medium, or high production volume. Utilizing the latest technologies, we are equipped to make any part for our customers. We have implemented in-line processing at these facilities to ensure every shipment is inspected to the most vigorous quality control measures.

At Adapt Technologies, you can count on us to deliver quality and innovation to help your company succeed. Ask us how we can help you

Electrical